WHAT DO YOU NEED TO CUT?

| Verdi BASIC | Verdi TWIN | Wincut | Inblade | Inblade PRO | Inbest BASIC | Inbest TWIN | Inbest PRO | ||

|---|---|---|---|---|---|---|---|---|---|

| Download table |  |

|

|

|

|

|

|

|

|

| CUTTING SYSTEM | SAW | SAW | BLADE | INTERCHAN. HEADS | INTERCHANGEABLE HEADS | INTERCHANGEABLE HEADS | |||

| RIGIDS | |||||||||

| PVC Foamboard | 20 mm | 20 mm | 5 mm | 5 mm | 13 mm | 5 mm / 10 mm** | 10 mm | ||

| Dibond® | 12 mm | 12 mm | - | - | 4 mm | - | - | - | |

| ChromaLuxe® | 3 mm | 3 mm | - | - | 1 mm | - | - | - | |

| Plexiglas® | 12 mm | 12 mm | - | - | 6 mm* / ♦ | 6 mm* / **/ ♦ | 4 mm* / ♦ | 4 mm* / ♦ | 4 mm* / ♦ |

| MDF / Wood | 20 mm | 20 mm | - | - | 4 mm | - | - | - | |

| Glass | - | - | 6 mm* / ♦ | 6 mm ♦ | 6 mm* / ♦ | - | - | - | |

| SEMI-RIGIDS | |||||||||

| Foamboard | - | - | 20 mm | 20 mm | 13 mm / 20 mm* | 13 mm / 20 mm* | 13 mm / 20 mm* | 13 mm / 20 mm* | |

| Cardboard | - | - | 20 mm | 20 mm | 13 mm / 20 mm* | 13 mm / 20 mm* | 13 mm / 20 mm* | 13 mm / 20 mm* | |

| Re-board® | - | 20 mm | 13 mm | 13 mm / 20 mm* | 13 mm / 20 mm* | 13 mm / 20 mm* | 13 mm / 20 mm* | ||

| Corrugated plastic | 20 mm | 20 mm | 5 mm | 5 mm | 13 mm | 13 mm | 13 mm | 13 mm | |

| Passepartout | - | - | Yes | Yes | Yes | Yes | Yes | Yes | |

| FLEXIBLES | |||||||||

| Fabric / Textiles | - | - | - | Yes | Yes | Yes | |||

| Plastic film | - | - | - | Yes | Yes | Yes | |||

| Banner materials | - | - | - | Yes | Yes | Yes | |||

| Paper | - | - | - | Yes | Yes | Yes | |||

| Vinyl | - | - | - | Yes | Yes | Yes | |||

| Magnetic sheets | - | - | - | Yes | Yes | Yes | |||

| V-GROOVE | |||||||||

| Dibond® | - | - | 4 mm* | - | - | - | |||

| Re-board® | - | - | 20 mm* | - | - | - | |||

| Foamboard | - | - | 13 mm* | - | - | - | |||

| MÁX. CUT | |||||||||

| All materials | 305 cm high | 305 cm high | 250 cm high | 305 cm high | 320 cm wide | 320 cm wide | 320 cm wide | ||

|

*Optional accessory required. **Possible but not for daily use ♦ Score and snap. |

|||||||||

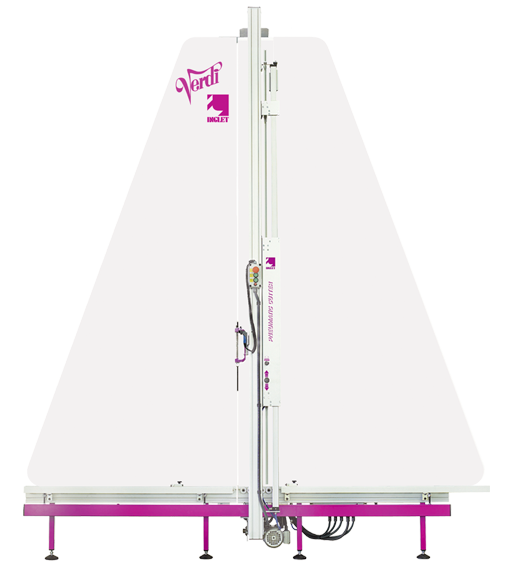

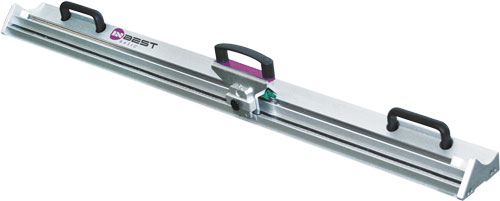

INBEST PRO Cutter Bar

The best investment for your workshop

The new InBest Pro cutter bar has been developed and constructed to satisfy all cutting requirements of a wide range of graphic materials; covering from the most delicate flexible material to any semi-rigid material.

The unique feature of using a linear bearing system to guide the cutting head guarantees an excellent performance and extreme precision, unmatched by any other cutter in the market.

The InBest Pro adds to the equipment an integrated aluminum base with two different cutting tracks: one with a narrow groove for general purposes, to be used with the knife blade; and other with a built-in cutting strip, to be used with the circular blade.

The InBest Pro is also equipped with an integral lift and hold mechanism, which can be used from both sides, to facilitate the material loading.

All InBest models are available in five different sizes: 110 cm (44”), 160 cm (63”), 210 cm (82”), 260 cm (102”) and 320 cm (126”).

Materials cut by Inbest Pro: PVC Foamboard, Acrylics / Plexiglas®, Foamboard, Cardboard, Honeycomb / Re-board®, Corrugated plastic, Passepartout, Fabric / Textiles, Plastic film, Banner materials, Paper, Vinyl, Magnetic sheets.

Includes:

• Cutting head for semi-rigid materials (up to 13 mm). Ref. 45 22 95.

• Circular blade for flexible materials (up to 4 mm). Ref. 45 22 96.

Cutting features

| RIGIDS | Interchangeable heads |

| PVC Foamboard | 10 mm |

| Acrylics / Plexiglas® | 4 mm * / ♦ |

| SEMI-RIGIDS | Interchangeable heads |

| Foamboard | 13 mm / 20 mm * |

| Cardboard | 13 mm / 20 mm * |

| Honeycomb / Re-board® | 13 mm / 20 mm * |

| Corrugated plastic | 13 mm |

| Passepartout | Yes |

| FLEXIBLES | Interchangeable heads |

| Fabric / Textiles | Yes |

| Plastic film | Yes |

| Banner materials | Yes |

| Paper | Yes |

| Vinyl | Yes |

| Magnetic sheets | Yes |

|

* Optional accessory required. ♦ Score and snap. |

|

Why is it different?

LINEAR BEARING SYSTEM

ERGONOMIC HANDLE SYSTEM

BLOCKING THE BLADE

INTERCHANGEABLE CUTTING TRACK

LIFT AND HOLD MECHANISM

FREE WORKING AREA

Other features

• User-friendly machine easy and simply to install.

• Plastic strip for sight line to visualize the cutting line and avoid guesswork need.

• Both the cutter and the aluminum base are equipped with full length grip strips to aid clamping and protect printed media

• Cutting thickness up to 20 mm for semi-rigid materials.

• Dust free operation to safely work close to printers.

En

En  Es

Es  Fr

Fr  De

De