WHAT DO YOU NEED TO CUT?

| Verdi BASIC | Verdi TWIN | Wincut | Inblade | Inblade PRO | Inbest BASIC | Inbest TWIN | Inbest PRO | ||

|---|---|---|---|---|---|---|---|---|---|

| Download table |  |

|

|

|

|

|

|

|

|

| CUTTING SYSTEM | SAW | SAW | BLADE | INTERCHAN. HEADS | INTERCHANGEABLE HEADS | INTERCHANGEABLE HEADS | |||

| RIGIDS | |||||||||

| PVC Foamboard | 20 mm | 20 mm | 5 mm | 5 mm | 13 mm | 5 mm / 10 mm** | 10 mm | ||

| Dibond® | 12 mm | 12 mm | - | - | 4 mm | - | - | - | |

| ChromaLuxe® | 3 mm | 3 mm | - | - | 1 mm | - | - | - | |

| Plexiglas® | 12 mm | 12 mm | - | - | 6 mm* / ♦ | 6 mm* / **/ ♦ | 4 mm* / ♦ | 4 mm* / ♦ | 4 mm* / ♦ |

| MDF / Wood | 20 mm | 20 mm | - | - | 4 mm | - | - | - | |

| Glass | - | - | 6 mm* / ♦ | 6 mm ♦ | 6 mm* / ♦ | - | - | - | |

| SEMI-RIGIDS | |||||||||

| Foamboard | - | - | 20 mm | 20 mm | 13 mm / 20 mm* | 13 mm / 20 mm* | 13 mm / 20 mm* | 13 mm / 20 mm* | |

| Cardboard | - | - | 20 mm | 20 mm | 13 mm / 20 mm* | 13 mm / 20 mm* | 13 mm / 20 mm* | 13 mm / 20 mm* | |

| Re-board® | - | 20 mm | 13 mm | 13 mm / 20 mm* | 13 mm / 20 mm* | 13 mm / 20 mm* | 13 mm / 20 mm* | ||

| Corrugated plastic | 20 mm | 20 mm | 5 mm | 5 mm | 13 mm | 13 mm | 13 mm | 13 mm | |

| Passepartout | - | - | Yes | Yes | Yes | Yes | Yes | Yes | |

| FLEXIBLES | |||||||||

| Fabric / Textiles | - | - | - | Yes | Yes | Yes | |||

| Plastic film | - | - | - | Yes | Yes | Yes | |||

| Banner materials | - | - | - | Yes | Yes | Yes | |||

| Paper | - | - | - | Yes | Yes | Yes | |||

| Vinyl | - | - | - | Yes | Yes | Yes | |||

| Magnetic sheets | - | - | - | Yes | Yes | Yes | |||

| V-GROOVE | |||||||||

| Dibond® | - | - | 4 mm* | - | - | - | |||

| Re-board® | - | - | 20 mm* | - | - | - | |||

| Foamboard | - | - | 13 mm* | - | - | - | |||

| MÁX. CUT | |||||||||

| All materials | 305 cm high | 305 cm high | 250 cm high | 305 cm high | 320 cm wide | 320 cm wide | 320 cm wide | ||

|

*Optional accessory required. **Possible but not for daily use ♦ Score and snap. |

|||||||||

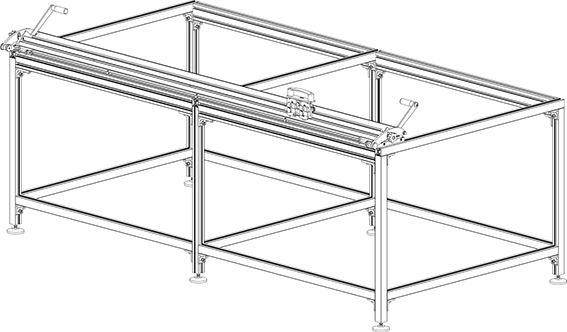

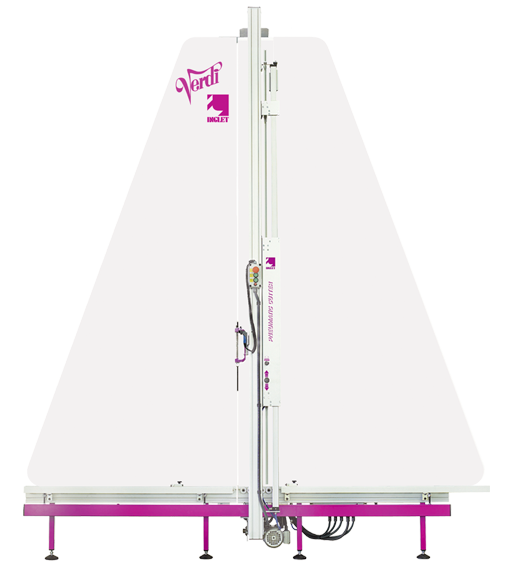

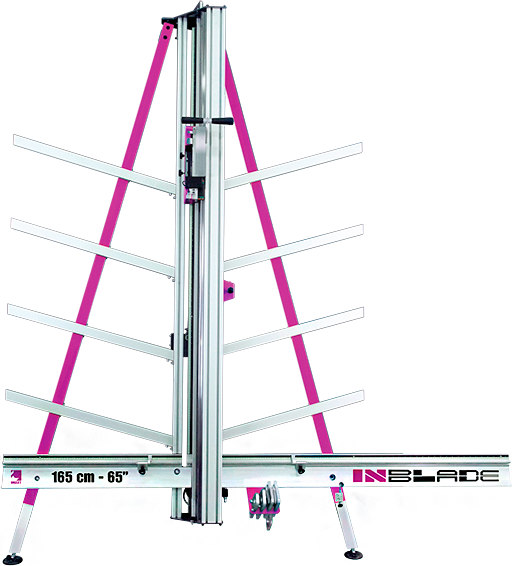

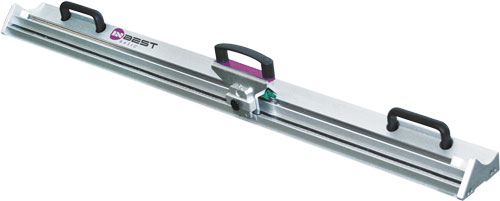

INBEST PRO 2.0 Cutter Bar

InBest Pro Table Cutter 2.0: Precision, Versatility and Outstanding Performance

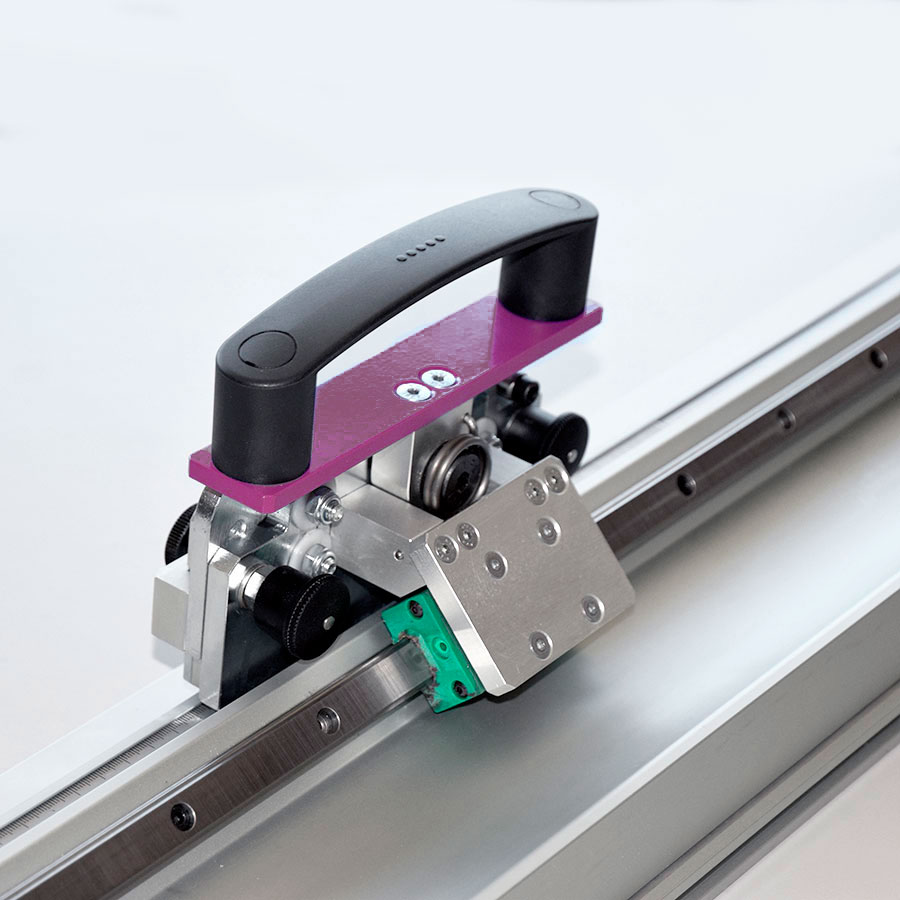

The InBest Pro 2.0 table cutter has been designed and built to meet all cutting needs across a wide range of graphic materials, from the most delicate flexible media to demanding semi-rigid substrates. Its advanced design ensures exceptional performance and extreme precision, thanks to a unique linear bearing system that guides the cutting head with unmatched smoothness and accuracy.

Available in five sizes —110 cm (44”), 160 cm (63”), 210 cm (82”), 260 cm (102”) and 320 cm (126”)— the InBest Pro fits a variety of production requirements and workspaces. It features an integrated aluminium base with two distinct cutting channels: one with a narrow groove for general use with the standard blade, and another with an integrated cutting base for circular blades.

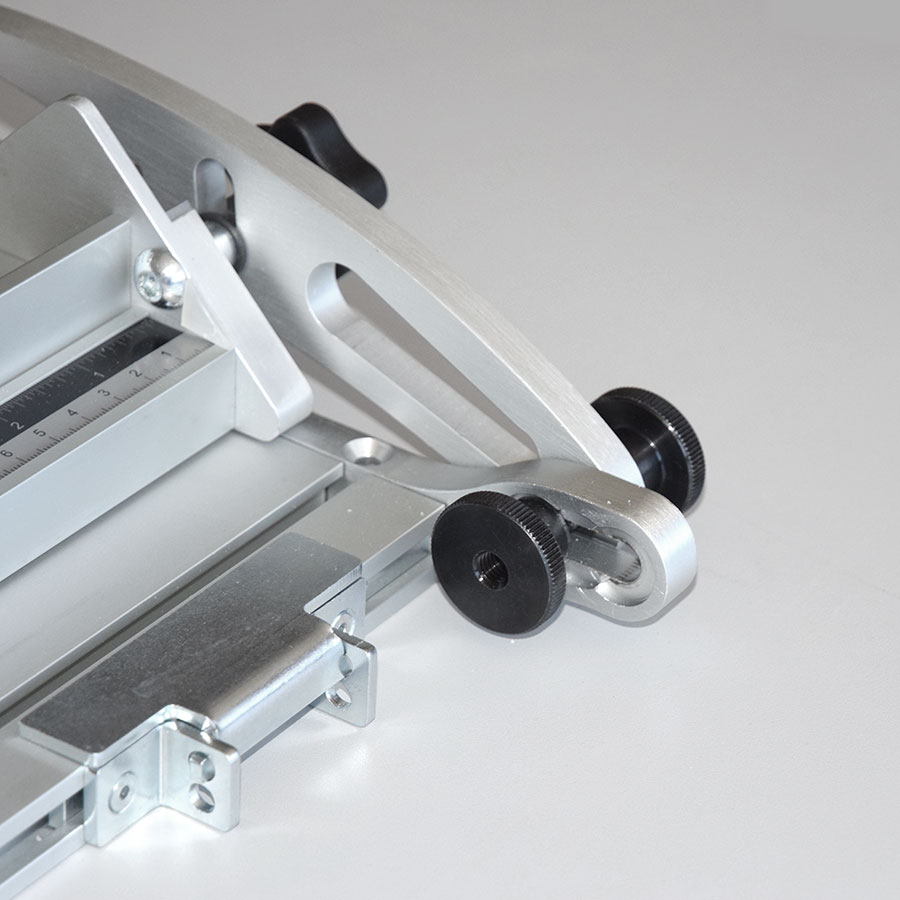

One of the most innovative features of the InBest Pro is its integrated lifting and clamping mechanism, accessible from both sides, which simplifies material loading and enhances user ergonomics. Version 2.0 introduces a completely redesigned lifting system, significantly improving usability and cutting precision.

This new system allows the cutting head guide to rise completely parallel to the base, keeping perfectly aligned with the material surface. As a result, there is continuous visibility of the cutting line, regardless of material thickness.

Additionally, the semi-elevated position keeps the cutter suspended just above the material without the need for manual support. This enables more accurate alignment, enhances working comfort, and optimises operational efficiency during cutting.

The InBest Pro is the ideal solution for those seeking quality, precision and versatility in every cut.

Includes:

• Cutting head for semi-rigid materials (up to 13 mm). Ref. 45 22 95.

• Circular blade for flexible materials (up to 4 mm). Ref. 45 22 96.

Cutting features

| RIGIDS | Interchangeable heads |

| PVC Foamboard | 10 mm |

| Acrylics / Plexiglas® | 4 mm * / ♦ |

| SEMI-RIGIDS | Interchangeable heads |

| Foamboard | 13 mm / 20 mm * |

| Cardboard | 13 mm / 20 mm * |

| Honeycomb / Re-board® | 13 mm / 20 mm * |

| Corrugated plastic | 13 mm |

| Passepartout | Yes |

| FLEXIBLES | Interchangeable heads |

| Fabric / Textiles | Yes |

| Plastic film | Yes |

| Banner materials | Yes |

| Paper | Yes |

| Vinyl | Yes |

| Magnetic sheets | Yes |

|

* Optional accessory required. ♦ Score and snap. |

|

Why is it different?

LINEAR BEARING SYSTEM

ERGONOMIC HANDLE SYSTEM

BLOCKING THE BLADE

INTERCHANGEABLE CUTTING TRACK

LIFT AND HOLD MECHANISM

FREE WORKING AREA

Other features

• User-friendly machine easy and simply to install.

• Plastic strip for sight line to visualize the cutting line and avoid guesswork need.

• Both the cutter and the aluminum base are equipped with full length grip strips to aid clamping and protect printed media

• Cutting thickness up to 20 mm for semi-rigid materials.

• Dust free operation to safely work close to printers.

En

En  Es

Es  Fr

Fr  De

De